Swedish high-tech company Acconeer supports German Start-up Packwise

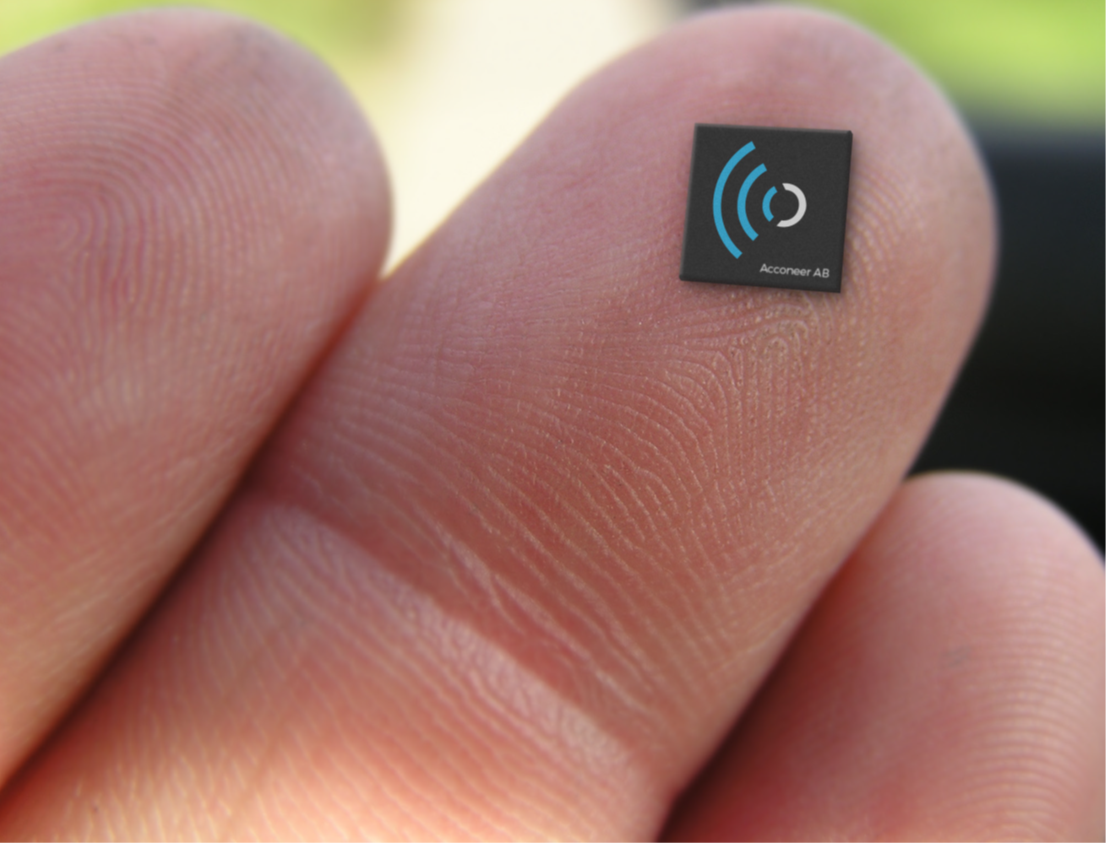

The interaction of two innovative solutions will open up new possibilities in container logistics in the future. The Dresden-based start-up Packwise and the Swedish technology company Acconeer are now working together. Acconeer, a spin-off from Lund University, developed a unique radar sensor. The sensor is now being used for the first time to measure fill level in a product targeting IBC tanks. Packwise is pursuing this with its own development Packwise Smart Cap. So a new possible application has been found for the super smart basic technology of Acconeer.

A few months ago the Dresden-based company was looking for the right technology to achieve the desired level measurement. Developer and CTO René Bernhardt did a lot of research. He tested numerous solutions from other suppliers. None was perfectly suitable. Then he came across the A1 radar sensor from Acconeer. „Even the first discussions with the Swedes were very constructive and the cooperation was uncomplicated right from the start,“ says Bernhardt. It quickly became clear that the sensor met the requirements. „The people responsible at Acconeer were immediately hooked on our topic and even got their own container to carry out initial tests.” At a joint workshop in Lund, the cooperation was further explored and finally settled by contract.

The joint project marks the last major step towards series production of the Packwise Smart Cap. The plug&play-device creates the digital twin of a container. Sensor data provide information about its location, fill level, movement, inclination and temperature. The Packwise Smart Cap, which can be attached to the container in a few easy steps, must therefore function perfectly – even under demanding conditions. A challenge for the technology, which the A1 radar sensor from Acconeer masters perfectly. It measures the distance between the top edge of the container and the liquid level. The level can be determined from this. Major advantage: the sensor can measure through a wide variety of materials without coming into contact with aggressive chemicals or highly sensitive container contents. Whether high and low temperatures or humidity – the measuring results remain absolutely precise.

After the suitability of the Acconeer sensor was confirmed with prototypes, the integration of the sensor into the Packwise solution was started as a joint project. The implementation challenges included algorithm adjustments, integration of hardware components and special software versions for the Packwise Smart Cap hardware architecture. Even after that, during the test phase, there was a lively exchange between the technicians of both companies. Acconeer employees visited the Packwise team in Dresden in order to optimise the technology for pilot Smart Cap customers. „The cooperation is very lively, fast and trusting,“ Packwise CEO Gesche Weger describes it. „We are very grateful for this warm and professional cooperation.“

Intermediate Bulk Containers (IBC) are mainly used in the chemical, pharmaceutical and food industries. According to estimates there are 43 million plastic IBCs in circulation within the EU. In addition there are almost three million steel IBCs. Series production of the Packwise Smart Cap will start this summer. The cap can be easily attached to the various models of IBC or steel drums. Because customers will have a better overview of stock levels, re- ordering can be automated and the logistics and preparation of containers can be improved. Carbon dioxide can be saved that would otherwise be produced in the production of new containers. An asset for the environment. „This is an innovative and absolutely forward-looking approach that Packwise is pursuing with the Smart Cap,“ says Lars Lindell, CEO of Acconeer. This development supports the idea of a circular economy. „We are delighted to be part of it now with our radar sensor technology.“ Both companies will continue to work closely together in the future.