In the chemical industry, liquid and granulated products should ideally be stored and transported in IBC containers. These containers have many benefits: they’re versatile, practical, stable and reusable. Yet one capability is missing from these true logistics all-rounders: agility.

An IBC container is an analog object in a digitalized world: a world that is constantly changing and presenting companies with new challenges on an almost daily basis. Supply chains are interrupted due to pandemics, customers demand a larger product quantity at short notice, a raw material becomes scarce – production has to be rescheduled, shipments redirected and new supply networks established.

Companies depend on being able to react to unforeseen events in an agile manner – yet they can only do so to a limited extent, as their IBC fleet is virtually invisible during operations. The current status of an IBC is only visible to the person making their way to its location. Such conditions make monitoring, managing and controlling the packages a cumbersome task, while handling also entails a high degree of manual effort.

The solution to this problem? Smart digitalization and automation. In this blog post, you’ll discover how IBC containers are becoming tools for transparency, efficiency and agility in the chemical industry with the help of digital twins and the Industrial Internet of Things (IIoT).

Digital Twins in the Chemical Industry

What does it take to make an analog system digitally comprehensible and controllable? Well, you need a digital copy of it, otherwise known as a digital twin. Digital twin technology creates a digital image of the IBC container that behaves exactly like the real IBC container.

To do this, it uses components from the world of the Internet of Things:

- Sensors: provide data on the container’s current operating status

- Connectivity: the technical ability to connect to a network

- Data structure: creates the basis for analysis and forecasts

- User interface: platform that compiles data and makes it visible

Put simply, this is how it works in practice at a chemical company: you install a smart sensor on the IBC containers in your fleet, which records the parameters of the container permanently or using interval measurements.

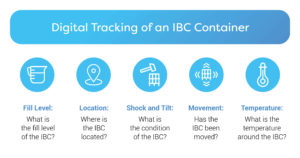

- Fill level: What is the fill level of the IBC?

- Location: Where is the IBC located?

- Shock and tilt: What is the condition of the IBC?

- Movement: Has the IBC been moved?

- Temperature: What is the temperature around the IBC?

The digital twin is built using the data you collect. This is connected to all other IBC twins in the fleet and the user interface, e.g. a web application or your ERP system. The IBCs form the nodes of the network, with data being created across the entire fleet.

The highly relevant data that is linked together opens up completely new analysis possibilities: you can see at a glance how many of your containers are filled, where they’re located and which of them are at risk of being damaged. However, displaying the real-time situation doesn’t mean you’ve unleashed the full potential here; you can also use the data to simulate if-then scenarios.

The benefits of a digital twin:

- No matter where the physical container is located, the user interface always maintains a detailed image that you can access from anywhere. Your delivery is stuck in Italy while you’re sitting at home? You can still retrieve the exact fill level or temperature of the container.

- The digital twin uncovers operational weaknesses and provides the basis for optimization with a data-driven analysis of the digital model.

- The collected data enables you to look into the future, serving as a decision-making and planning aid for highly complex, dynamic processes in warehousing, production and logistics.

- The technology underpinning the digital twin lays the foundation for new processes and business models.

With the help of digital twin technology, you can transform industrial packaging into smart, connected IoT devices. Incidentally, many industries are already making intensive use of the opportunities afforded by the Internet of Things: an estimated 13.8 billion IoT devices are currently in use worldwide, with this figure set to rise to almost 20 billion by 2023.

Use Cases and Benefits of Digital Twins and IoT on the IBC Fleet

As already mentioned, conventional handling of IBC containers lacks transparency and control. It’s complex, data-intensive and characterized by mutual dependencies. That’s why your container logistics in particular will benefit enormously from the opportunities offered by the Internet of Things; it even represents the ideal use case.

A fully connected IBC fleet:

- Enables you to use packaging more efficiently and move through the packaging cycle faster → lower material costs and capital deployed

- Remains efficient for longer because you receive an early warning about critical conditions (temperature, shock) and can take proactive measures → quality management becomes more effective

- Enhances customer relationships because more data is available → improved customer loyalty

- Minimizes manual effort thanks to automated processes, e.g. reordering or picking up containers → reduces staff deployment

The last point will become increasingly important for tomorrow’s chemical industry. Automated IBC fleet management runs largely independently of slow, expensive and time-consuming human tasks. The digitalized IoT containers can react to external influences and changes in the supply chain directly and without any delays.

- Material and goods flows are controlled according to predefined guidelines.

- Distribution processes can be planned digitally and executed automatically.

- Automatic stock control facilitates management of the IBC container.

- Re-orders are made purely on the basis of real data without human intervention.

Intelligent Fleet Management with Packwise Smart Cap

Are you interested in taking the efficiency and transparency of your packaging to a new level? Would you like to finally have more control over your IBC containers? It’s really easy with Packwise Smart Cap and the Packwise Flow platform.

Which of them are at risk of being damaged. However, displaying the real-time situation doesn’t mean you’ve unleashed the full potential here; you can also use the data to simulate if-then scenarios.

The Smart Cap attaches to your IBC containers in just a few simple steps, turning it into a connected IoT device. Using the digital twins in the app, you receive unprecedented insights into your IBC fleet. You can keep your packaging in circulation longer, remain informed about product stock at your customer’s site, and reap the benefits of optimized quality management.

We look forward to answering your questions about a smart, automated IBC fleet and will be happy to advise you on your personal situation. Get in touch!

Discover more valuable information about the digital connectivity of your IBC fleet in our free white paper “Smart IBC Containers and Industrial IoT in the Process Industry: Improve Customer Service, Design Sustainable Supply Chains and Automate Processes” – download it here!